RTCA DO-254, “Design Assurance Guidance For Airborne Electronic Hardware”, is primary guideline to producing airborne electronic hardware whose latest version is published in 2000. RTCA DO-254 specifies the design lifecycle requirements for avionic systems and provides guidelines for the airworthiness of aircraft electronic hardware. DO-254, like DO-178, was also released in collaboration with the RTCA and EUROCAE. DO-254, in 2005, formally accepted by the FAA to respond to the increasing use of various electronic gear in airborne systems.

DO-254 compliance helps you improve the safety of passengers, crew and operator, strengthens your business. Moreover, it provides your company a competitive advantage since some projects require DO-254 compliance, and you will have an advantage over other manufacturers and developers that do not provide it.

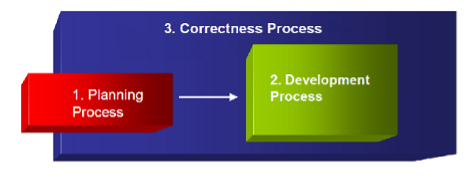

Main processes for DO-254 certification can be summarized as

- Planning Process

- Development Process

- Correctness Process

It is important to notice that development process should start after the completion of planning process, whereas correctness process should be carried out throughout the project.

DO-254 standards should be satisfied by documents such as:

- PHAC (Plan for Hardware Aspects of Certification)

- HVP (Hardware Verification Plan)

- HVP (Hardware Validation Plan)

- HPAP (Hardware Process Assurance Plan)

- HAS (Hardware Accomplishment Summary)

Some DO-254 documents may resemble DO-178 documents. Our DO-178 checklists are available for review and purchase here.

DO254 Documents

PHAC

PHAC (Plan for Hardware Aspects of Certification) should be produced in the planning process and get approved by the authority. PHAC reflects an agreement between the certification applicant and the certification authority on the procedures and actions to be carried out, as well as the resulting proof to be generated, in order to fulfill the hardware aspects of certification. In the context of this plan, the developer describes its strategy and how DO-254 is implemented. To check our PHAC document, please click here.

Hardware Verification & Validation Plan

Hardware Verification Plan checks whether the hardware meets the design specifications. Hardware Validation Plan, on the other hand, is used to check that the hardware meets the operational needs of the user. The basic distinction between verification and validation, as stated in the preceding definitions, is the environment in which tests are performed. The accuracy of the design is checked against the design specifications in a verification flow. The accuracy of the design is evaluated against the demands of the intended user during the validation flow. These documents also should be prepared as a part of planning process.

HPAP

HPAP (Hardware Process Assurance Plan) checks whether the hardware design lifecycle processes and data are defined and also conformed with the approved plans. The methods for meeting the hardware design assurance objectives, including defined strategies, are proposed to the certification authority. To check our HPAP document please click here.

HAS

HAS (Hardware Accomplishment Summary) informs the certification authority on what was accomplished on the hardware side. The difference between PHAC and HAS is, with PHAC you told the certification authority what you were planning to do, whereas with HAS you tell them what you actually did. HAS should also specify any deviations from the approved PHAC. HAS should comprise hardware identification information, hardware status, version history and compliance statement. It also looks like Software Accomplishment Summary, which is a checklist for DO-178 conformity. It should contain the following sections; system and hardware overview, hardware design lifecycle description, hardware lifecycle data. To check our HAS document please click here.

Design Phases

Preliminary Design Phase

Preliminary design begins with the functional baseline established during conceptual design and progresses to the work of translating system-level functional needs into design requirements for the subsystems that will be merged to form the system. This translation necessitates continuing the requirements analysis begun in conceptual design. Specific needs for the system’s hardware, software, and employees must be defined. Trade-off analyses are carried out, and the preliminary design work results in the construction of an allocated baseline, in which needs are assigned to individual subsystems that comprise the system.

Critical Design Phase

Critical design phase is a multi-disciplinary technical process that ensures a system can proceed to manufacture, demonstration, and testing while meeting stated performance criteria within cost, time, and risk constraints. The product baseline is initialized during the critical design phase. The objective of the critical design is to evaluate a system’s final design as defined in product specifications for each configuration item in the system’s product baseline and to confirm that each configuration item has been included in the detailed design documentation.

Critical design phase is completed by conducting Critical Design Review. CDR assures that the system can move forward to testing and production. It also expresses that the mentioned requirements can be met within budget and schedule. The comprehensive drawings and specifications that arise provide an initial product baseline, with a final baseline. CDR should be thorough and exhaustive.

Final Design Phase

The Final Design Phase includes precise architectural and technical drawings of each project component. It may be important to generate a final design report for some projects. Before completing the final design process, all detected design issues must be resolved. The drawings and report must be detailed enough to provide for relatively accurate estimates of construction and operation costs, as well as construction timelines. A revised timeframe, cost estimates, and requirements should be included in the final design report. It should also be authorized that the project is financially feasible. Any changes made during the Final Design Phase are more expensive than those made throughout the preceding phases. As a result, it should be done with great care.

Author: Can Önal ([email protected])

Mor Teknoloji

Mor Teknoloji